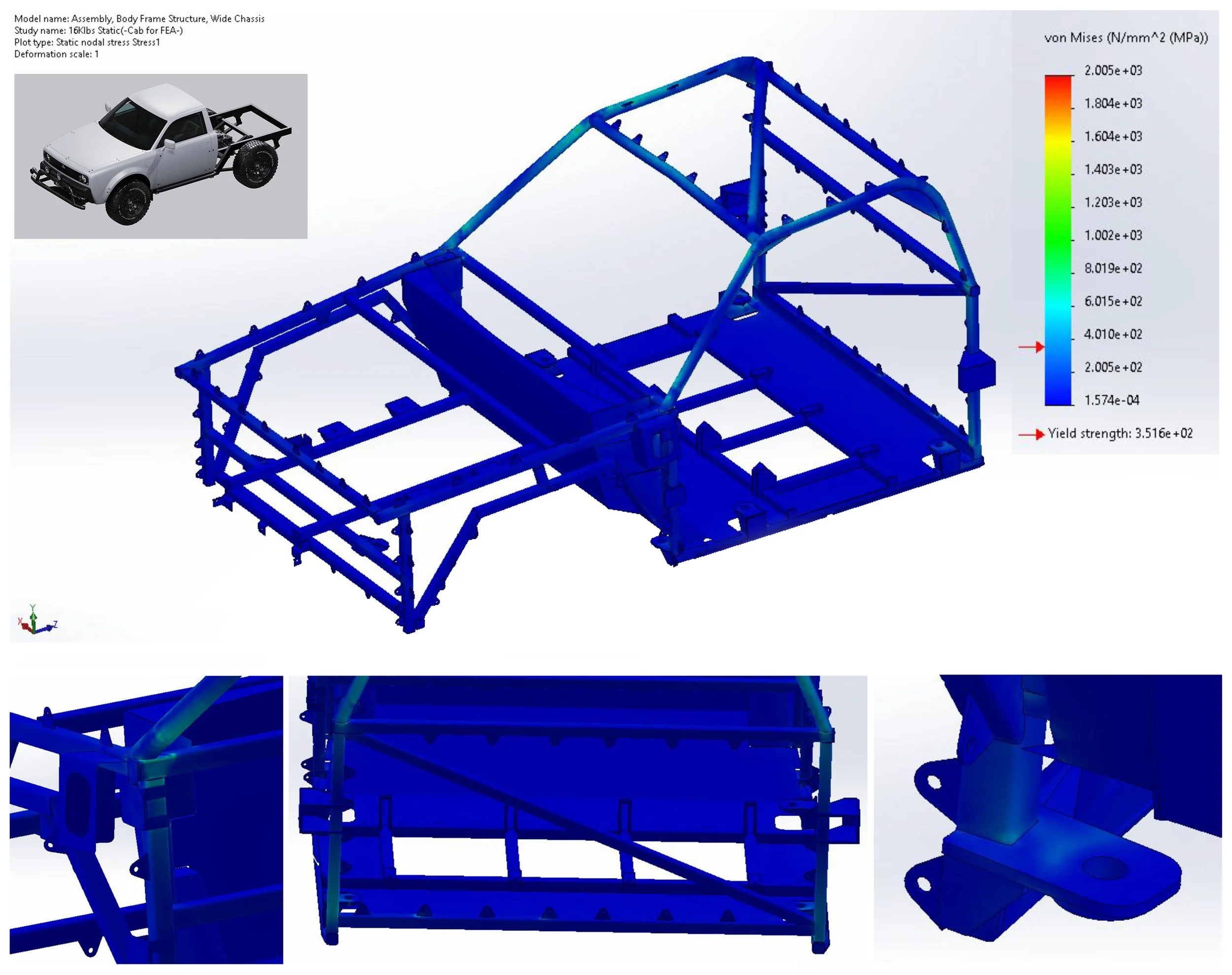

Vehicle Structure FEA Testing

The WOLF Truck Withstands Over 16,000lbs of Stress, Performing Beyond Good Looks

"Alpha is efficiently achieving high-quality vehicle construction, effectively advancing preproduction through straightforward engineering solutions, establishing strong fundamentals. Furthermore, by simplifying our technology for scalability, our solutions boost the development of Alpha’s entire EV lineup." - Alpha Motor Corporation

In a previous report, we outlined Alpha's commercialization process, streamlining high product quality across a diverse range of electric vehicles. This process speaks to Alpha’s unique application of virtual validation, where advanced simulation tools, including Finite Element Analysis (FEA), analyze rigidity to assess how materials and designs withstand dynamic forces. Von Mises stress identifies potential areas of concern for yielding or failure, ensuring a comprehensive evaluation of structural worthiness before the development of physical prototypes.

Below are the FEA results of stress testing a demo version of the WOLF vehicle structure. The results reveal that the frame of the WOLF successfully withstands 16,000lbs. of pressure without any critical failure. This is nearly four times the projected weight of the WOLF electric truck.

16,000LBS. on Cabin, 1,000lbs. on Front - Von Mises Overview