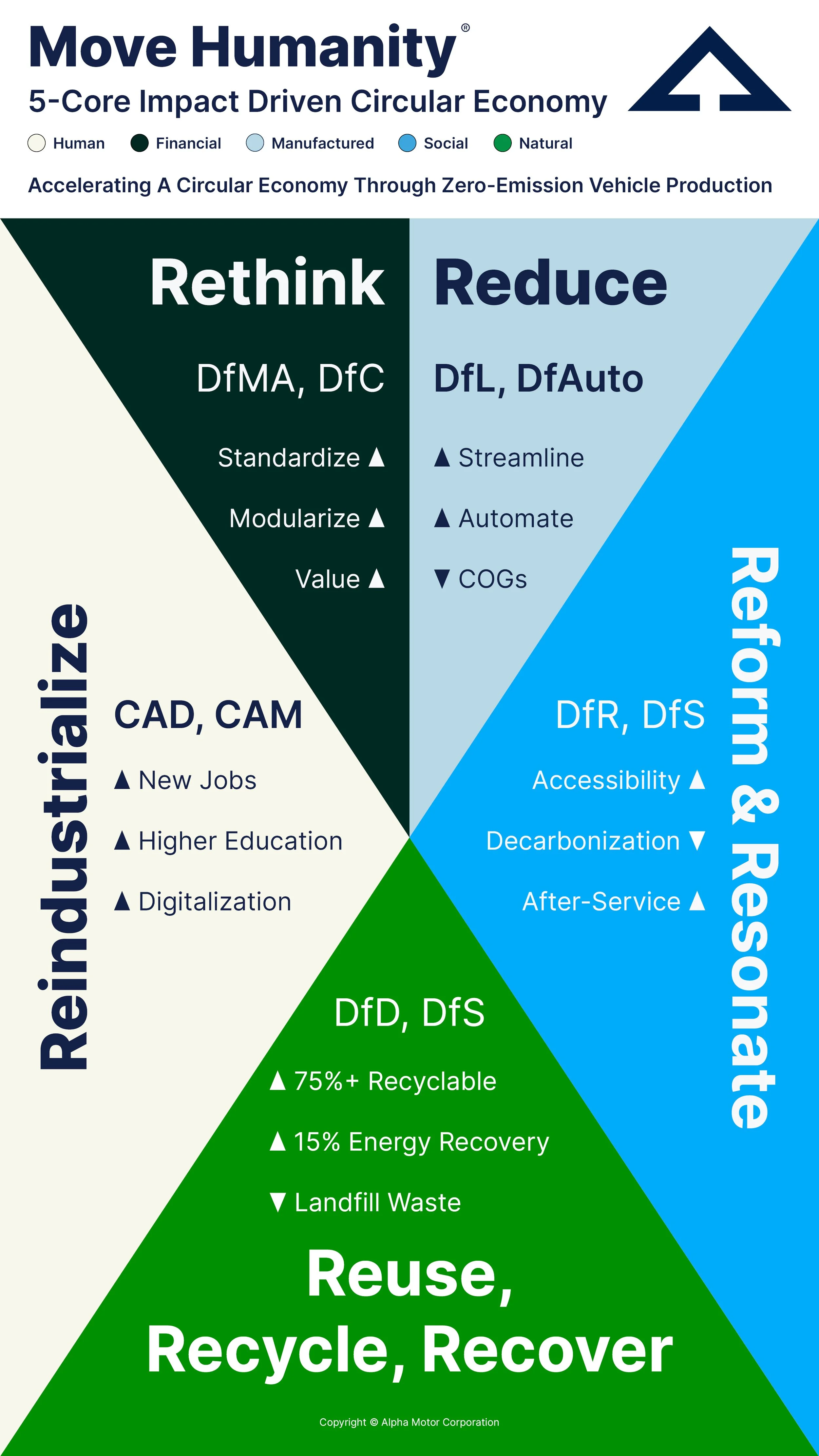

5-Core Impact Driven Circular Economy

How Alpha Motor Is Driving a Circular Economy Through Zero-Emission Vehicles

Move Humanity® means we're rethinking what it means to manufacture sustainably and how transportation can regenerate value across human, financial, manufactured, social, and natural systems. Our 5-Core Impact Driven Circular Economy is rooted in engineering excellence and designed to scale positive outcomes through the lifecycle of our zero-emission vehicles.

The 5-Core Impact Framework

We structured our model around five actionable principles that define a modern, circular manufacturing system:

Rethink

Reduce

Reform & Resonate

Reindustrialize

Reuse, Recycle, Recover

Each of these pillars aligns with specific engineering methodologies and design-for-impact principles. Together, they accelerate sustainability, enable digital manufacturing, and reinforce Alpha’s commitment to driving systemic change.

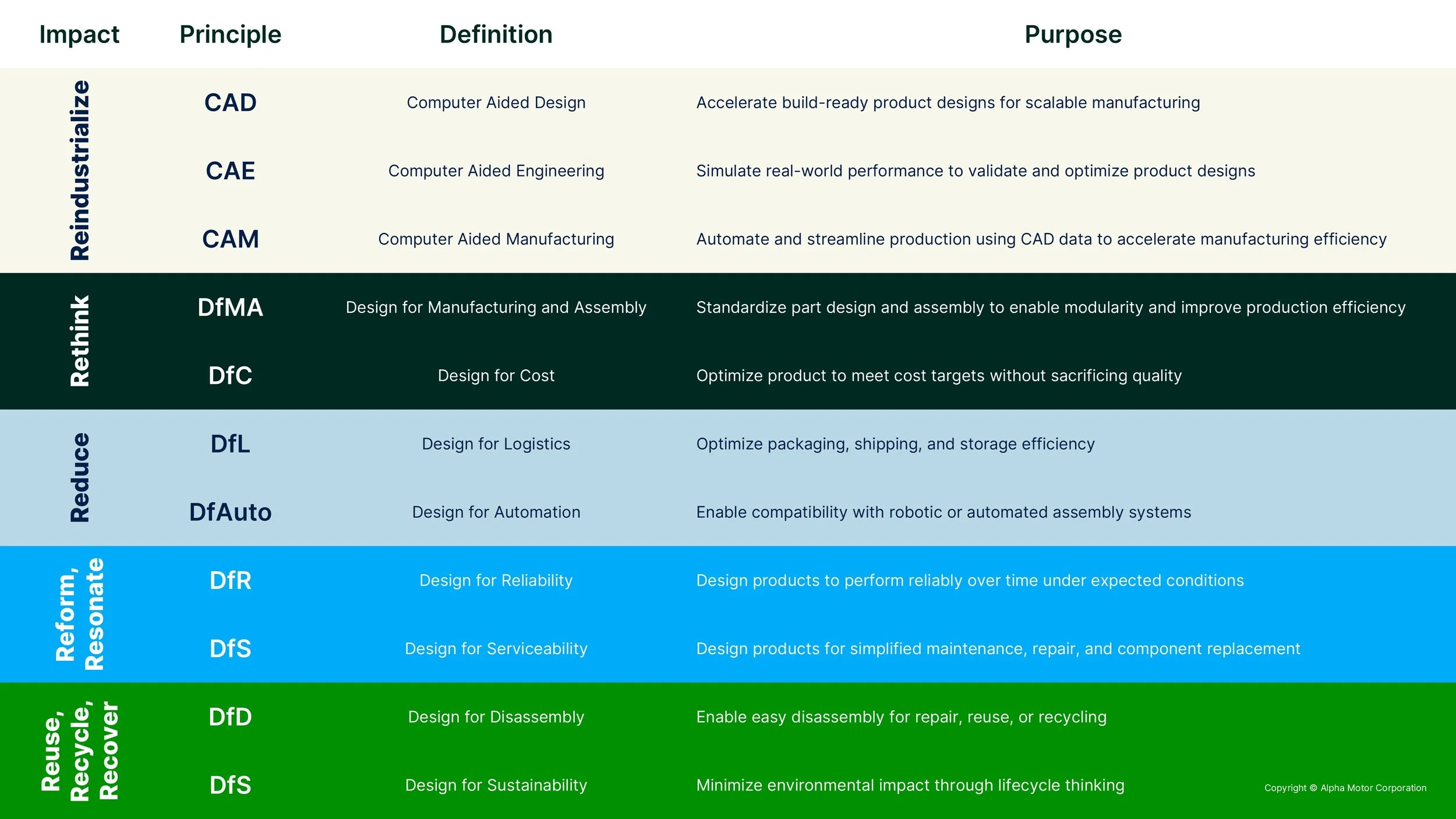

Rethink: Design for Value

By integrating DfMA (Design for Manufacturing and Assembly) and DfC (Design for Cost), we rethink every component at the engineering stage. This means:

Standardizing parts across platforms

Modularizing systems for scalability

Increasing vehicle value while maintaining cost efficiency

This approach empowers us to create flexible, affordable vehicles while significantly lowering the barrier to entry for mass production.

Reduce: Streamlining and Automating the Build Process

Through DfL (Design for Logistics) and DfAuto (Design for Automation), Alpha reduces both waste and complexity:

Simplifying packaging and shipping

Enabling robotic compatibility

Lowering Cost of Goods Sold (COGS)

Automation and logistics-aware design aren't just operational advantages—they’re key drivers of environmental and financial efficiency.

Reform & Resonate: Building Reliability and Serviceability

Our design process integrates DfR (Design for Reliability) and DfS (Design for Serviceability) to support the long-term ownership experience:

Enhancing product longevity

Simplifying maintenance and component replacement

Driving decarbonization through extended lifecycle use

We aim to make every Alpha vehicle not just a product, but a long-lasting platform for clean mobility.

Reindustrialize: Empowering Jobs and Innovation

With tools like CAD (Computer-Aided Design), CAE (Computer-Aided Engineering), and CAM (Computer-Aided Manufacturing), Alpha is reindustrializing the American automotive sector:

Creating skilled jobs

Elevating digital education

Powering new manufacturing ecosystems

Our circular strategy revitalizes domestic industry while aligning with global clean tech trends.

Reuse, Recycle, Recover: Designing for Circularity

We build every vehicle using DfD (Design for Disassembly) and DfS (Design for Sustainability):

Over 75% of parts recyclable

15% energy recovery built into system design

Minimization of landfill waste

Sustainability is not an afterthought—it’s embedded into the DNA of our vehicles from concept through end-of-life.

The Bigger Picture: Circular Impact Across All Five Dimensions

Each of these five principles targets a core area of impact:

Human – Job creation, serviceability, and education

Financial – Cost optimization, capital efficiency

Manufactured – Modularized production and digital tools

Social – Accessibility and long-term usability

Natural – Emissions reduction and material circularity

By harmonizing all five, Alpha Motor isn’t just building electric vehicles—we’re building a regenerative business model designed for real-world impact.

Move Humanity® is a call to rethink, reengineer, and reignite how we build the future of transportation.

Learn more about how we’re engineering change at www.alphamotorinc.com.